With Black Friday and Peak sales just around the corner, efficiency and productivity are more important now than ever. In order to meet high demand, proper use of automation has become an essential tool for businesses looking to streamline their packaging processes. By integrating packaging machines into your warehouse operations, you not only reduce manual labour but also enhance accuracy, sustainability and overall workflow. A number of businesses have solutions for automating picking but as it stands, packaging is still largely dependent on operators. Using machinery can help these operators to perform more efficiently and helps to reduce the risk of repetitive strain injuries.

Below, we explore how specific packaging machines can help optimize your warehouse processes, from pick to dispatch, ensuring your packaging operations goes as smoothly as possible.

What is Warehouse Automation?

Warehouse automation is the process of using machinery and software to improve warehouse performance by automating repetitive manual tasks and leaving operators to perform work that requires hands-on planning. As specialists in packaging, the automation we provide is focused on this element of the operation rather than picking and packing, in particular we have machines that can help in filling a box, sealing a box and preparing a pallet. By automating this work, you can ensure consistency of the pack and efficiency in the number of lines completed.

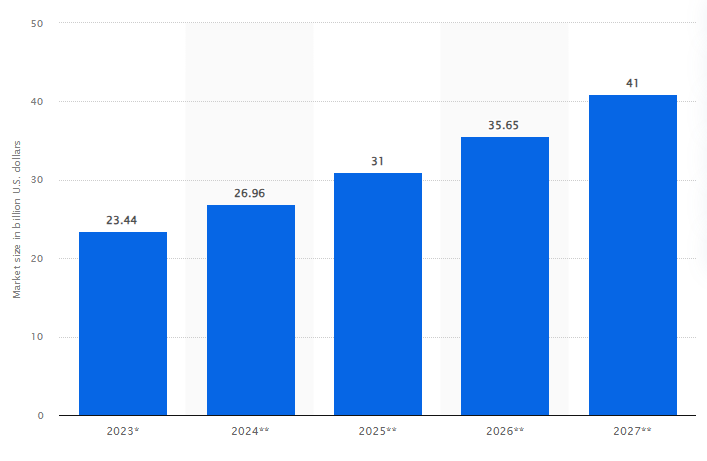

The global market size for warehouse automation is expected to increase and be worth $31 billion by next year (source) which makes it all the more important that you make sure your operations are making the most of the available technology in all elements of your warehouse operation!

Packaging Machines: Efficient Paper Void Fill Solutions

One of the key challenges in packaging is ensuring that products remain secure during transit. Packaging machines that use paper as void fill are an excellent solution for filling empty spaces in boxes, protecting items from shifting and damage. These machines are designed to feed paper efficiently into boxes, making the void fill process faster and easier for warehouse staff. One of the best machines available is the Fillpak TTC which can be loaded with Fillpack Padpak Paper.

The beauty of these paper-based systems lies in their simplicity and sustainability. Not only are they easy to stock with additional stacks of paper but they can help standardise how much paper is used and help to control how much void fill us used. Plus, the use of recyclable paper enhances your warehouse’s commitment to sustainable practices while offering robust protection for your goods with much better storage efficiency- one block of Fillpak TTC paper provides as much void fill as 3 full bags of EcoFlo! Interested in seeing if these could help? Check out our post about renting Packaging Machines and see if we can help you!

Tape Machines: Precise and Sustainable Tape Application

Taping boxes manually can often lead to inconsistent applications, excess tape use, and even product damage. That’s why using machines like the OM700 can be a brilliant way to help keep costs down while still improving the performance of your tape. These machines dispense precise lengths of water-activated tape, which is not only more secure but also offers a sustainable, biodegradable alternative to traditional plastic tapes.

By automating this step, you ensure that each package is sealed consistently with the exact amount of tape needed—no more, no less. This helps to minimise tape wastage, which in turn reduces costs. Water-activated tape also forms a stronger bond with cardboard, improving the integrity of your parcels during shipping. And the paper tape, once more, can help your packaging to be more environmentally conscious. Why not check out our full range of gummed tape dispensers to see what other eco conscious solutions we have to offer.

Stretch Wrap Machines: Consistency and Safety for Pallet Wrapping

Last but not least in the packaging journey, the pallet wrap. Wrapping pallets manually is not only labour-intensive but requires a best guess of how much wrap to use. Stretch wrap machines provide a more reliable and efficient solution, ensuring that every pallet is wrapped uniformly and securely. This consistency is crucial in maintaining the integrity of the goods, especially during long-distance shipping or when the products are stored in high-demand environments. This is why machines like the Ecoplat Turntable machine can make all the difference for a busy workplace.

In addition to offering better protection, stretch wrap machines reduce the repetitive movements that manual pallet wrapping requires. These repetitive motions can lead to strain or injury for warehouse staff, but automating this task minimizes those risks, making the workplace safer. Moreover, stretch wrap machines can be programmed for specific load sizes and shapes, ensuring optimal use of wrapping materials, thus cutting down on unnecessary waste. Of course, we also have strapping machines if that’s how you choose to handle your pallets.

By implementing these technologies, you’re not just speeding up your operations—you’re ensuring that every package is prepared, sealed, and shipped with the highest standards of accuracy and care, all while reducing your environmental footprint. Get in touch with us today to learn how you can improve your own business operation with warehouse automation!