Creating custom printed boxes for brand recognition is a great way to elevate your brand and products when customers see them online, in stores and when they arrive via courier or in the post.

But what do you need to do to create the perfect branded box? Read on

Creating custom printed boxes for brand recognition

Custom-printed boxes can be like works of art (Image: PXHere)

Creating custom printed boxes for brand recognition is an ideal way to elevate your product. Not only will it make the box look nicer and more enticing to users, but it can also turn what is essentially protective packaging for storage or transit into something that can build brand, create loyalty and lead to further sales.

Brand box marketing is an established way to meld packaging and brand marketing to create awareness around your product, brand and company by simply printing logos on packaging boxes.

Just a nice looking pattern and your logo on the box can work wonders. The look and feel of packaging and the unboxing experience is vital these days for creating a good impression of your brand – an impression that can also garner you positive reviews online and on social media.

Adding information such as a web address, discount codes or data about the goods can be really useful and, if worked into a beautiful design, can also be an attractive addition to the box.

But it’s about much more than just the aesthetic of having a customised cardboard box. Printing the right information on your boxes and getting the right creative working on it can not only cement the brand-customer relationship, but also be used to up-sell and cross-sell, offer discounts and loyalty benefits and, increasingly, act as a means of linking the physical world of packaging with the digital world via mobile phones.

Interactive packaging opens a whole new world up to brands through simply working some elements into the box design and printing. Simple QR codes, worked into an informative design, can give more details on the products, the brand, the sustainability and recycling attributes of the products, or even information about how to reuse the box. Anything is possible.

Bring all these together to create an excellent ‘look and feel’ along with useful information and a gateway into more online is what custom box printing is all about.

So what are the practicalities?

Packaging box printing

A simple logo can make a box so much more (Image: PXhere)

Packaging box printing offers all of these benefits, but you have to work out how best to do it. The first port of call is to select the right cardboard boxes.

Selecting the right size box for your items is the first step. Once you have that you need to work on how best to print your designs and information on to the box.

There are many ways of doing this, depending on the material of the box, the cost and the level of intricacy of the design. So what are the options?

- Litho printing – Litho printed cardboard boxes are photo quality boxes images that are best for printing not only words and logos, but also images of the products inside. Litho printing is also suited to large print runs, so it is your best bet if you are looking to print a lot of boxes. Litho printing uses a plate with the images and text etched into it that is then covered in ink and pressed onto the box. It can be done in up to four colours and has the advantage of mass-printing. The ink also dries very quickly.

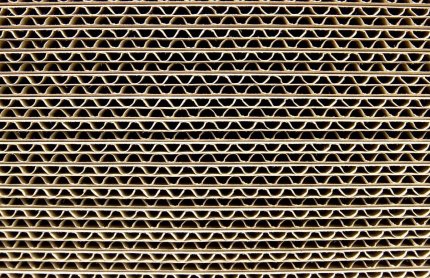

- Flexo printing – flexo printing on boxes is similar to lithographic printing (litho) only it uses a flexible plate – hence the name flexographic printing – and is used to print on curved or corrugated surfaces. This is ideal for box printing of logos and brand names, as well as useful information such as ‘this way up’ and ‘fragile’ (although there are loads of stickers for this too).

- Digital printing – digital printed cardboard boxes are different again and involve printing directly onto the box from either inkjets or using xerographic printing. Inkjet digital printing uses a fine spray of black, cyan, magenta and yellow inks to create the colour and design needed. Xerographic digital printing, on the other hand, uses electrostatic charging to charge ink particles and then apply them to the box. Both forms of digital printing are used to create designs of odd shaped boxes, corrugate boxes and is the most economical way of printing.

- Screen printing – screen printing on cardboard boxes involves pushing ink through the holes in a screen of fabric, holes that are designed to be different thicknesses depending on how much ink they let through and allowing for the creation of tonal images. Screen printing is ideal for bold and blocky designs, particularly on fabric and fine card like materials. Screen printing for packaging is typically used on bags.

Branded packaging boxes

Branded packaging boxes have been a means to success for years (Image: lan Levine/PXHere)

So what kinds of branded packaging boxes can you create? Really the only limit is your imagination, but there are some basic principles to bear in mind.

The most obvious place to start is with logo printed boxes. These are boxes that have your logo printed on them, either just on the lid or around the whole box. A simple logo, even just a monochrome image on the card of the box, can be very effective if well designed and well placed. If combined with coloured boxes – maybe even ones that compliment or highlight one of your corporate colours – can lift even a simple logo and transform the box into a nice piece of physical marketing.

Such brown box branding can be extended to also include company name, address, website and even images – all of which really enhance the look and feel of the packaging. They also take all that is great about a cardboard box and elevate it into a work of art – a work of art that can also help you win and keep customers.

Want to know more about our wide range of perfectly sized cardboard boxes?

For additional advice on a wide range of perfectly sized cardboard boxes, our Experts are here to help you find the right solutions and arrange next day delivery. Simply call us on 0800 542 44 28 or visit www.rajapack.co.uk