When it comes to packaging, how you seal the finished box is as important as the box and void fill. The three major forms of sealant are strapping, tape, and stretch wrap. Each of these solutions offers distinct advantages and has versatile applications in the packaging world. In this post, we’ll explore the versatility of strapping, tape, and stretch wrap and delve into some different use cases in the packaging industry.

Tape: Versatility and Convenience

Tape is an indispensable tool in packaging, widely used for sealing cartons, boxes, and envelopes. Its versatility and convenience make it a go-to solution for businesses of all sizes. With a wide range of options available, including paper tapes, filament tapes, and masking tapes, you can choose the most suitable tape for your specific needs. Paper tapes offer good adhesion and are recyclable while filament tapes provide additional strength for heavy-duty applications. Masking tapes are ideal for temporary or delicate surfaces. Moreover, tapes can be customized with branding or warning messages, enhancing product identification and safety. However, tape isn’t suitable for particularly large or heavy packages and is best suited for small to medium boxes. For larger products, you need to

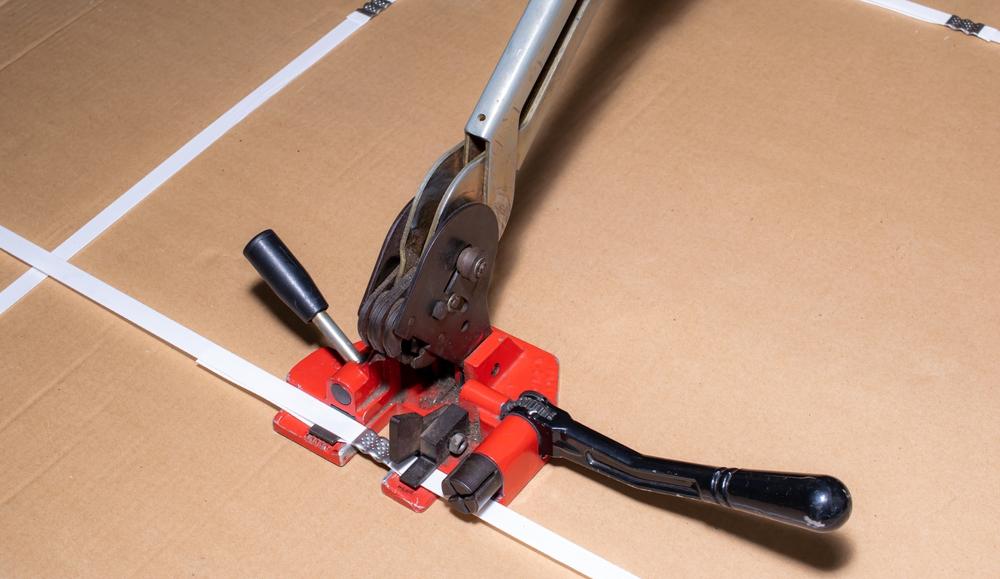

Strapping: Strength and Stability

Strapping, made of durable materials like steel or polyester, is renowned for its exceptional strength and ability to secure heavy loads. It’s even know available as paper strapping. Whether you’re bundling together large cartons or palletizing bulky goods, strapping provides the necessary strength and stability to prevent shifting and damage during transit. It finds extensive usage in industries such as construction, logistics, and manufacturing. Additionally, strapping can be tensioned using manual or automated tools, ensuring a tight and secure hold on your products. Its reliability and durability make it an excellent choice for demanding packaging requirements. For heavy or oversized items like furniture, strapping is the way to go.

Stretch Wrap: Protection and Stability

Stretch wrap, also known as stretch film, is a highly versatile packaging solution that provides excellent protection and stability to a wide range of products. Its primary purpose is to secure and bundle items together, preventing shifting, dust accumulation, and tampering during transit. Stretch wrap is particularly effective for palletized goods, offering load stability and minimizing the risk of damage. It adheres tightly to itself when stretched, creating a secure cocoon around the products. Additionally, stretch wrap can be applied manually or with the help of stretch wrap machines, ensuring efficient and consistent packaging processes. If you need to secure a whole pallet of goods, stretch wrap is the solution for you.

—-

Strapping, tape, and stretch wrap are essential components of the packaging industry, each offering distinct advantages and finding versatile applications. From the strength and stability of strapping to the convenience and versatility of tape, and the protective properties of stretch wrap, these tools enable businesses to package their products securely and efficiently. By understanding the diverse use cases of strapping, tape and stretch wrap, you can optimize your packaging processes, ensuring the protection and integrity of your goods during transportation and storage.